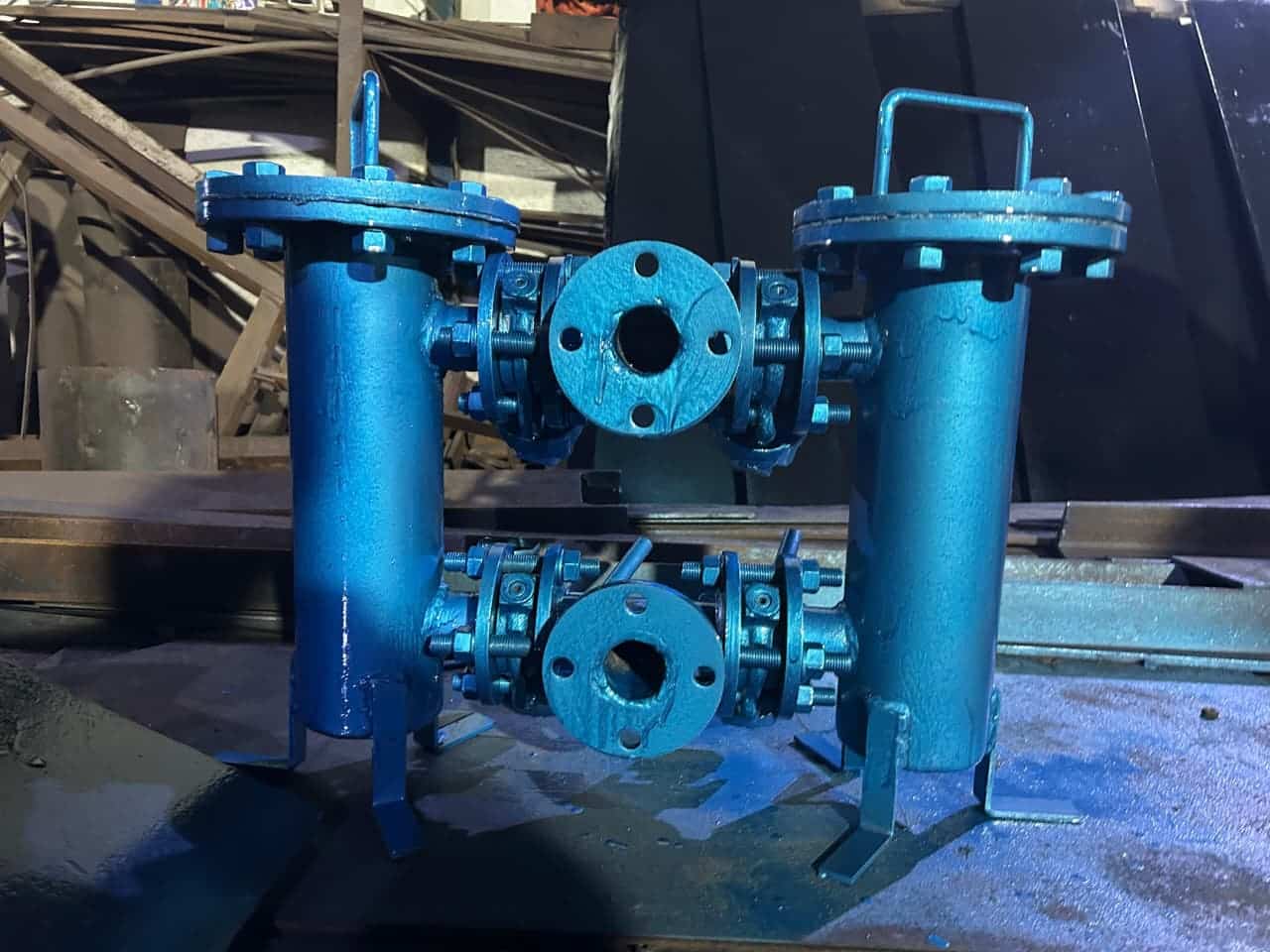

A duplex basket filter is an industrial filtration device designed for continuous operation without shutdown. It consists of two basket filter chambers arranged side by side and connected through a changeover valve or lever mechanism.

Working Principle:

- While one basket filter is in service, the other remains on standby.

- When the operating basket becomes clogged, flow is smoothly diverted to the standby basket.

- The clogged basket can then be cleaned or replaced without interrupting the process.

Key Features:

- Continuous filtration with no process downtime

- Quick and easy changeover mechanism

- High dirt-holding capacity

- Robust construction (commonly cast iron, carbon steel, or stainless steel)

- Removable perforated or wire-mesh baskets

Applications:

- Oil & gas pipelines

- Chemical and petrochemical plants

- Water treatment systems

- Power plants

- Pump and compressor protection

Purpose: Duplex basket filters are used to remove solid contaminants from liquids or gases, protecting downstream equipment such as pumps, valves, meters, and heat exchangers.